MIDNITE SOLAR

MidNite During The Covid-19 Pandemic.

Washington state has a stay at home order during the Covid-19 pandemic. Solar however is one of those essential industries allowed to continue working. Below is the MidNite employees that have volunteered to work during these troubling times.

|

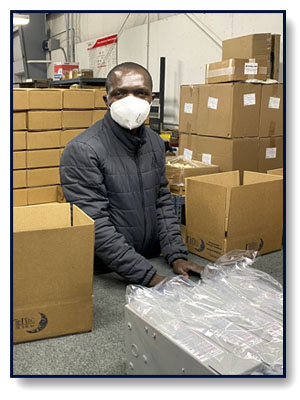

Gucci is building MNPV6 combiners, the most popular combiner in the world. He recently came to us from Africa. Gucci and his wife just had a new baby in February just as this whole pandemic mess started. They have three other children also. Gucci is glad to have a job to come to and we are glad to have him. |

|

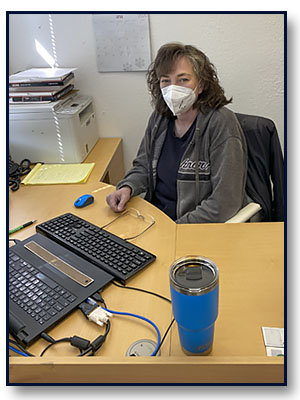

Tierney just moved into the main scheduler position from being our Shipping manager. We count on schedules being pretty accurate 6 months into the future. Without that we will have either too many parts of not enough. She may need a crystal ball for the upcoming products like Sunspec rapid shutdown, Barcelona, Hawke’s Bay, B17, B17-B and the Rosie. Good luck! |

|

Wayne, a former Marine is testing and programming the Classic MNGP’s (MidNite Graphics Panel). The MNGP’s talk, so how does he keep his sanity while verifying that each one says the right things? |

|

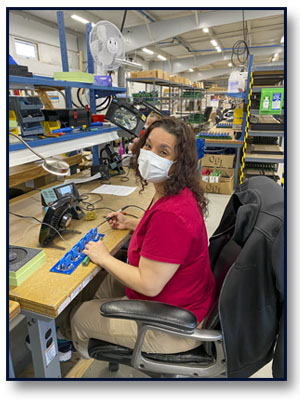

Lisa is soldering switches on the SPD’s using a very exotic solder. A lot of thought and process control has gone into our SPD’s. |

|

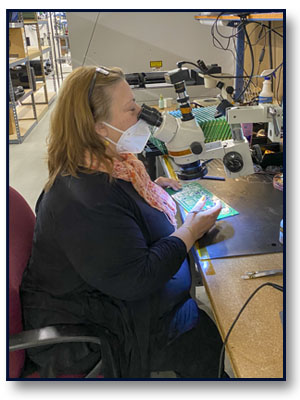

Cyndee is the lead of the SPD department. A few of our larger customers pleaded with us to keep shipping things like SPD’s and breakers as we are pretty much the only source for these products. Orders have not diminished for SPD’s. We are still shipping. |

|

Jose has been working with us and other local inverter companies for 20 years now. Jose is half of our warranty department and designs functional test equipment for production also. He is seen here working on a tester for a fet driver board. The B17 can use as many as 60 of these boards, so functional testing and calibration is very important. |

|

James and Irma: This is our pandemic crew Kid line. These two have by far the most experience building the Kid charge controller. The Kid continues to gain popularity with OEM’s due to its incredible feature set. We can’t stop their production lines so we continue to build Kids. |

|

Erik is our receiving clerk. He gets to ride around all day in an little green electric cart delivering parts to 4 of our 5 buildings. With parts spread out like this we often have to ask Erik where such and such parts are? |

|

Jim H is new to MidNite. He comes to us with an MBA in inventory and logistics. Jim is getting his feet wet in building 7 ,shipping, prior to moving into a management position. |

|

Bobbie is usually building our High Voltage combiners in building 3 or rapid shut down products in building 6. She was caught over in shipping this day. |

|

Josh is building Schneider XW E-Panels. Josh is one of those guys that we can throw at many special projects. He always has a positive attitude. |

|

Scott is building some E-Panels. Scott is usually building our Pre-wired systems using Magnum, Schneider, SMA or Samlex inverters. Scott, like many of our employees came to us from former local inverter companies that no longer build things in the USA. We are not going out of the country to build our equipment. |

|

Gordon with the new conformal coating drying system. Four CNC machines spray water based conformal coating, flip the boards and mask holes on the boards, then sprays the other side. Then the dryer heats the boards sprayed with coating for about two hours. The conveyors are up high so we can still have test and assembly benches underneath to conserve space. This system started out as three E-Bay dry cleaners conveyor systems. |

|

Tony building Classic inductors. After the coils are wound, they need to be squished so the cores will fit around the coils. After assembly of coils and cores the inductors are taken to the varnishing room. In the future we plan on automating the “squishing” process. I’m sure Tony and the rest of the Magnetics department won’t complain. |

|

Vicki inspecting a Classic power board. Right behind her is a new $100K automatic 3D optical inspection machine we just purchased. Due to the virus haven’t figured out how to use it yet. We expect to be inspecting a circuit board every 20 seconds one year from now, so we have to do something short of Cloning Vicki. |

|

Jeremy is making a batch of MNGP2 boards for Barcelona, Hawke’s Bay and B17 beta units. In the background is the SMT area. We have 25 SMT pick and place machines. |

|

Karen is inspecting MNGP boards prior to going through the oven. The SMT machines do well, but it still helps to give the boards a quick inspection prior to melting the solder paste in the oven. Rework is a snap at this level. We have three ovens. |

|

Lisa is applying solder paste on a panel of SPD boards. Solder paste is made of tiny balls of solder suspended in flux and is the consistency of toothpaste. The SMT pick and place machine places parts onto the paste where they stay untill going through the oven. We have three solder paste machines. |

|

Fran is one of our many employees that came to us through Trace Engineering and Outback Power. Fran is the lead in our combiner / sheet metal department. |

|

Shawn is in an office here, but during the pandemic like always, he is keeping tabs on every facet of manufacturing. |

|

Stephanie is one of three purchasing agents. She is responsible for breakers, semi conductors, resistors and capacitors. She also is the store keeper in building 6. Her husband is also part of our Kid department. |

|

Denise is our QC inspector and also doubles as document control. People from the different buildings call her on walkie talkies when they have batches of products to be inspected. Denise also rides her own Harley in her spare time. |

|

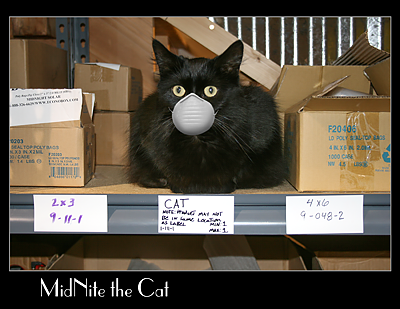

MidNite was a stray cat who saw a good thing when she first appeared at MidNite's door. She is now loved by everyone and the company mascot. |